China's Top 10 Hanger Bolt Companies: Leading Manufacturers and Suppliers

2026-01-06

Welcome to our deep dive into China's top players in the hanger bolt industry! If you're on the lookout for reliable manufacturers and suppliers, you've come to the right place. In this blog, we'll unveil the leading companies driving innovation and quality in this essential field, including standout names like Topfence, which is making waves with its cutting-edge solutions. Get ready to explore what sets these top 10 companies apart and how they're shaping the future of infrastructure and construction projects. Let's jump in and discover the best in the business!

Innovative Hanger Bolt Solutions: A Glimpse into China's Market Leaders

In recent years, China's manufacturing sector has made significant strides in hanger bolt innovation, with local leaders pushing the boundaries of design and functionality. Companies like Boltech Industrial and FastenPro China are at the forefront, developing solutions that cater to diverse applications from furniture assembly to heavy machinery. Their focus on precision engineering and durable materials has resulted in bolts that offer enhanced load-bearing capacities while minimizing installation time, making them a preferred choice for global partners seeking reliable fastening systems.

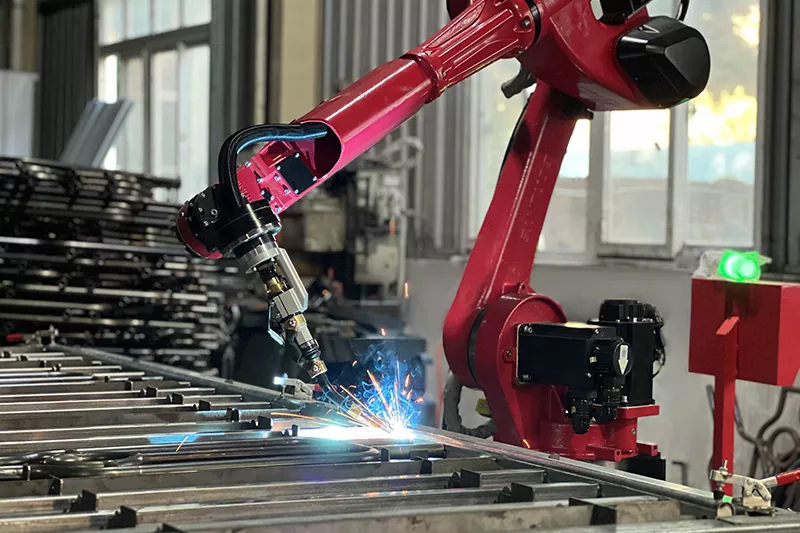

These market leaders often integrate advanced technologies such as automated production lines and quality control systems to ensure consistency and reduce defects. By leveraging smart manufacturing techniques, they can produce bolts with tighter tolerances and superior corrosion resistance, addressing common challenges in industries like construction and automotive. This proactive approach not only boosts efficiency but also allows for customization, enabling clients to specify unique thread patterns or coatings tailored to specific environmental conditions.

Beyond technical prowess, Chinese firms are gaining recognition for their agile supply chains and competitive pricing strategies. They actively engage in R&D to explore eco-friendly materials and energy-saving processes, reflecting a commitment to sustainability. As a result, their innovative hanger bolt solutions are increasingly adopted in international projects, solidifying China's role as a key player in the global fasteners market and offering insights into future trends in industrial fastening.

Quality Control and Manufacturing Excellence in China's Top Suppliers

China’s leading suppliers have redefined quality control through a blend of precision engineering and adaptive systems. Rather than relying solely on automated inspections, these firms integrate real-time data analytics with human oversight, allowing for rapid adjustments during production. This approach minimizes defects while maintaining flexibility across diverse product lines, from electronics to automotive components. Many top suppliers now employ predictive maintenance and AI-driven anomaly detection, which reduces downtime and enhances consistency, positioning them as reliable partners in global supply chains.

Manufacturing excellence in this context extends beyond traditional metrics like efficiency and cost-effectiveness. It encompasses sustainable practices, such as energy-efficient facilities and waste reduction initiatives, which not only meet international standards but also attract environmentally conscious clients. By investing in advanced technologies like 3D printing and IoT-enabled machinery, Chinese suppliers achieve shorter lead times and customisable outputs without compromising quality. This capability enables them to cater to niche markets and high-demand industries seamlessly.

What sets China’s top suppliers apart is their commitment to continuous improvement through cross-industry collaboration and skill development. They often partner with research institutions to innovate materials and processes, ensuring their manufacturing stays ahead of global trends. This proactive stance on quality and excellence allows them to navigate complex regulatory landscapes and deliver products that exceed expectations, fostering long-term trust with clients worldwide.

Diverse Applications of Hanger Bolts from Leading Chinese Companies

Chinese manufacturers have become industry leaders in hanger bolt applications, leveraging advanced materials like stainless steel and specialized alloys to ensure durability across harsh environments. This expertise allows for innovative uses in custom furniture assembly, where these bolts provide robust connections without visible hardware, and in artistic installations, where they support intricate metal sculptures securely.

Beyond traditional sectors, companies are pioneering solutions in renewable energy projects, such as solar panel mounting on uneven surfaces, using hanger bolts designed for high load-bearing and weather resistance. This versatility is backed by rigorous testing protocols, ensuring each bolt meets international standards while offering tailored options for unique client needs.

The adaptability extends to smart home systems, where hanger bolts are integrated into modular designs for easy reconfiguration, and automotive aftermarket parts, providing reliable fastening in retrofit applications. By continuously refining production techniques, Chinese firms deliver bolts that not only perform reliably but also enhance overall project efficiency and aesthetic appeal.

Global Reach and Export Success of China's Premier Manufacturers

China's premier manufacturers have redefined global reach by seamlessly integrating advanced technology with cost-effective production. Companies like Huawei in telecommunications and BYD in electric vehicles have expanded beyond domestic markets, establishing a strong presence in Europe, Southeast Asia, and Africa. This expansion isn't just about selling products abroad; it involves setting up local operations, adapting to regional regulations, and building trust through reliability and innovation, often outpacing established competitors in emerging economies.

Export success for these manufacturers hinges on strategic partnerships and agile supply chains that minimize disruptions. Firms such as Haier in home appliances have diversified their export portfolios, offering everything from high-end smart devices to budget-friendly options tailored to local tastes. By leveraging digital platforms and data analytics, they anticipate market trends and adjust production swiftly, ensuring a steady flow of goods even during global challenges like trade tensions or pandemic-related slowdowns.

Beyond hardware, China's manufacturing leaders are exporting expertise through services like infrastructure projects and technology licensing. This holistic approach strengthens their global footprint, turning short-term export gains into long-term influence in international trade circles.

Technological Advancements and R&D Initiatives in the Industry

One of the most notable trends in the industry is the fusion of artificial intelligence with traditional manufacturing processes. Companies are leveraging machine learning algorithms to optimize production lines, reducing waste and enhancing quality control. For instance, predictive maintenance systems now use sensor data to forecast equipment failures before they occur, minimizing downtime and saving costs. This integration not only boosts efficiency but also opens new avenues for customizing products to meet specific consumer demands.

Beyond AI, research and development efforts are heavily focused on sustainable technologies. Innovations such as carbon capture and utilization, or advanced recycling methods for plastics, are gaining traction as businesses strive to meet environmental regulations and consumer expectations. Collaborations between startups and established firms are accelerating these breakthroughs, with pilot projects demonstrating significant reductions in carbon footprints. This shift towards eco-friendly solutions is reshaping industry standards and creating competitive advantages for early adopters.

In addition, the rise of quantum computing is starting to influence R&D in fields like pharmaceuticals and materials science. By simulating complex molecular structures with unprecedented speed, researchers can design new drugs and materials more efficiently. Although still in its early stages, industry partnerships with academic institutions are driving progress, promising to unlock discoveries that were previously out of reach. These initiatives highlight a broader commitment to pushing technological boundaries beyond incremental updates.

Customer Support and Sustainable Practices Among Top Performers

In today's competitive landscape, leading companies are increasingly recognizing that exceptional customer support goes hand-in-hand with robust sustainable practices, creating a powerful synergy that drives long-term success. These top performers don't view these areas as separate silos; instead, they integrate them into a cohesive strategy where responsive, empathetic support teams address client concerns while also advocating for eco-friendly initiatives. By doing so, they build stronger brand loyalty and trust, as customers appreciate not only quick solutions but also a commitment to ethical operations that benefit the broader community.

What sets these high achievers apart is their proactive approach—they don't just wait for issues to arise but anticipate customer needs and environmental challenges. For instance, they might implement green technologies in their support centers, reduce waste through digital solutions, or train staff on sustainability topics to enhance communication. This forward-thinking mindset ensures that every interaction, whether resolving a complaint or promoting a new eco-friendly product, reinforces a positive brand image and aligns with modern consumer values.

Ultimately, the integration of customer support and sustainability among top performers leads to tangible benefits, such as reduced operational costs and increased customer retention. Companies that excel in this dual focus often see a ripple effect, where satisfied clients become brand ambassadors, spreading word-of-mouth about both quality service and environmental stewardship. In a world where consumers are more discerning than ever, this holistic approach isn't just a trend—it's a strategic imperative that sets the bar for industry standards.

FAQ

Leading Chinese hanger bolt companies excel in precision engineering, durability, and customization. They often invest in advanced machinery and materials like stainless steel, ensuring products meet international standards like ISO and ASTM. Strong supply chain networks and quick delivery times also set them apart from competitors.

Top suppliers implement rigorous quality control systems, including regular inspections and testing for tensile strength and corrosion resistance. Many use automated production lines to minimize human error and maintain batch-to-batch consistency, backed by certifications from global bodies.

Key industries include construction, furniture manufacturing, automotive, and aerospace. These sectors rely on hanger bolts for heavy-duty fastening in structural applications, where reliability and load-bearing capacity are critical.

The industry has shifted towards specialization and eco-friendly practices. Companies are now focusing on niche markets, adopting greener production methods, and leveraging digital tools for better customer service and inventory management to stay ahead.

Challenges include raw material price volatility and trade regulations. Leading companies mitigate this by diversifying suppliers, stockpiling key materials, and staying updated on global compliance standards to ensure smooth exports and operations.

It usually starts with a detailed inquiry or sample request. Suppliers provide technical consultations, custom quotes, and prototype testing. Once approved, they manage production with regular updates and offer after-sales support, ensuring a seamless experience from order to delivery.

Innovations include smart fasteners with embedded sensors for real-time monitoring, lightweight composite materials for enhanced performance, and automated installation solutions. These advancements help meet demands for efficiency and sustainability in various applications.

Conclusion

China's top hanger bolt companies have established themselves as market leaders through innovative solutions and advanced manufacturing. These manufacturers consistently deliver high-quality products by implementing robust quality control systems and embracing technological advancements. Their commitment to research and development drives continuous improvement, ensuring their offerings meet diverse industrial needs, from construction to automotive applications.

Beyond product excellence, these top performers excel in global exports, leveraging customer-centric support and sustainable practices to build international trust. Their success stems from a balanced focus on precision engineering, environmental responsibility, and adaptability to market demands, solidifying China's position as a premier supplier in the global hanger bolt industry.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/